The Art of Bronze

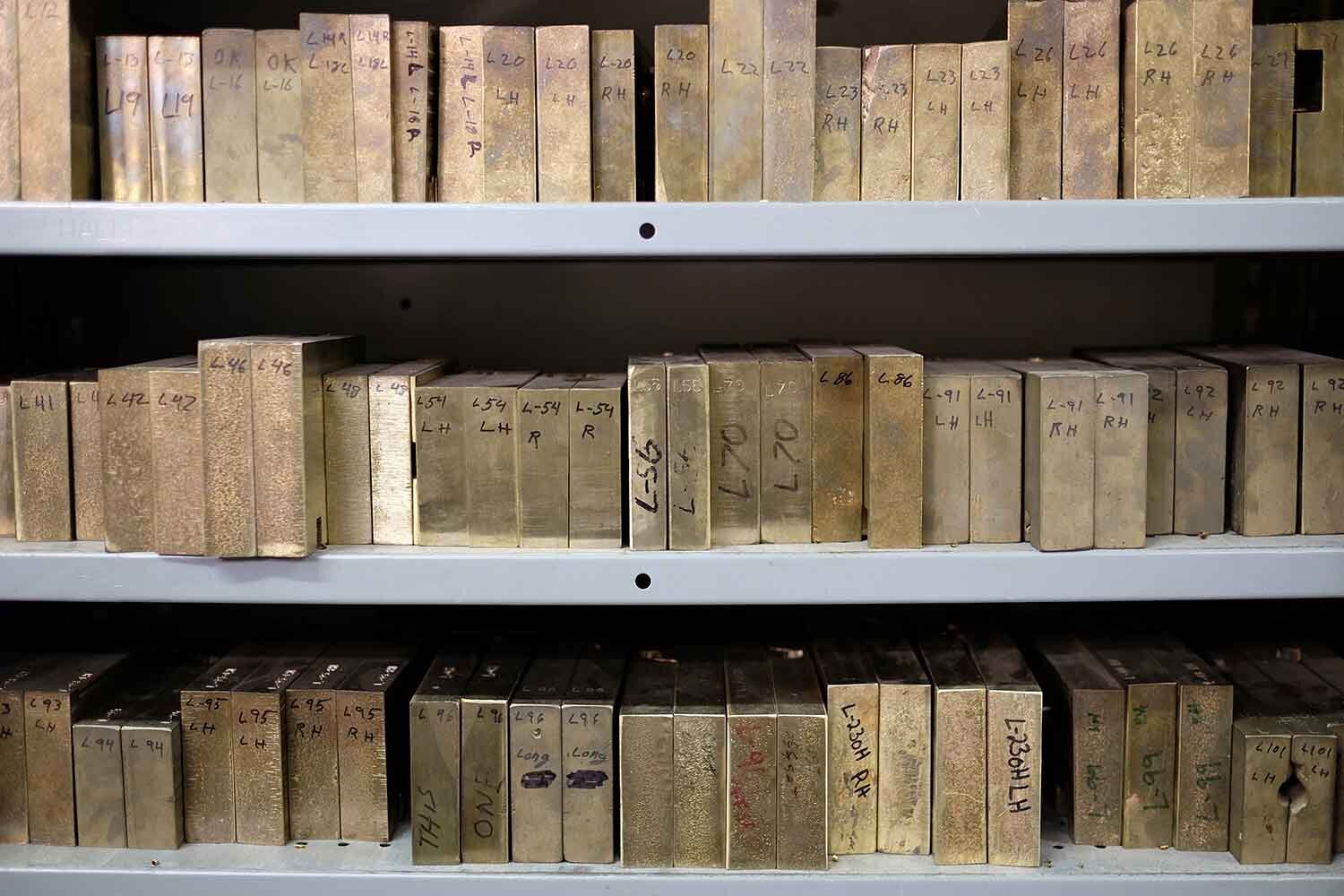

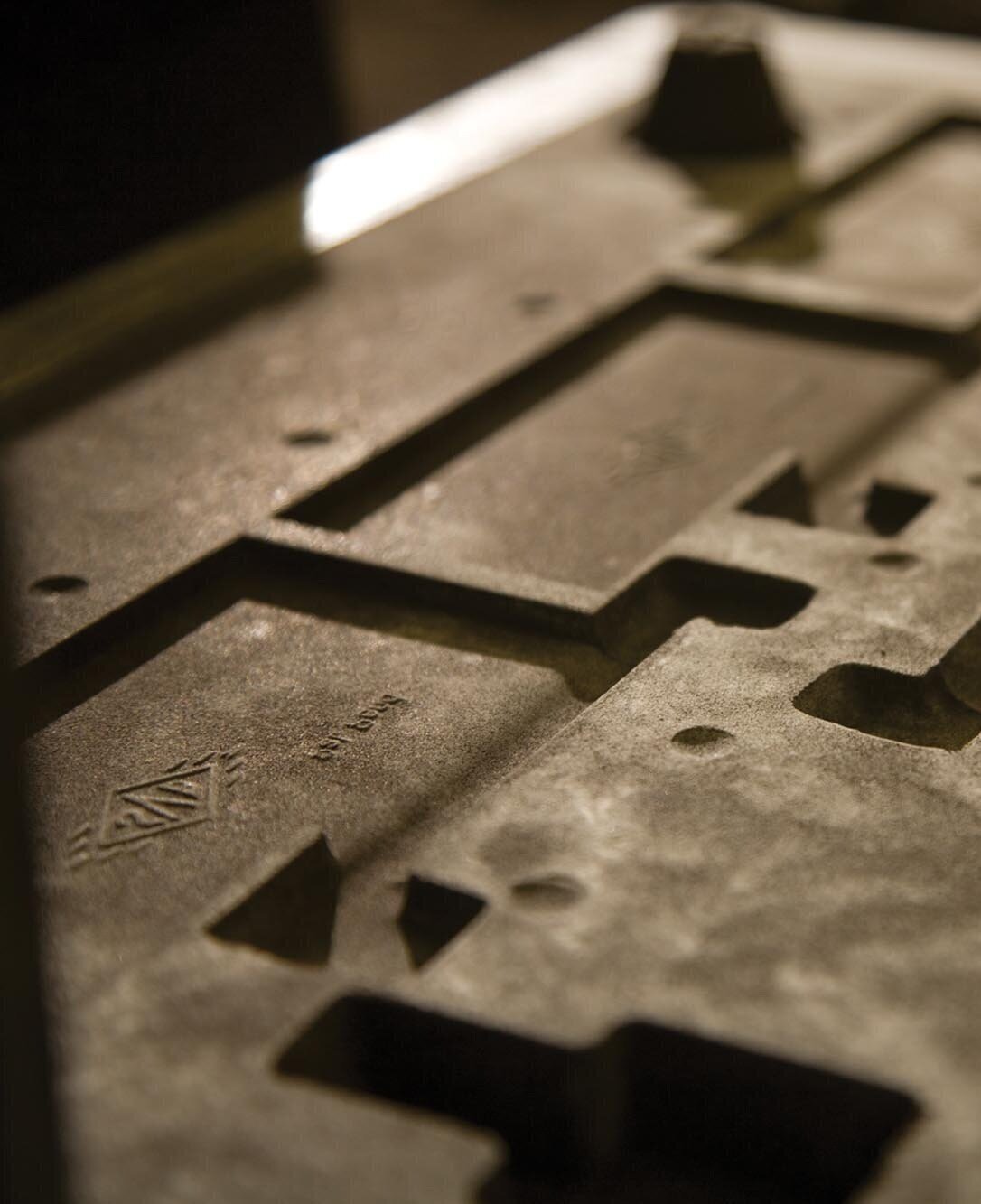

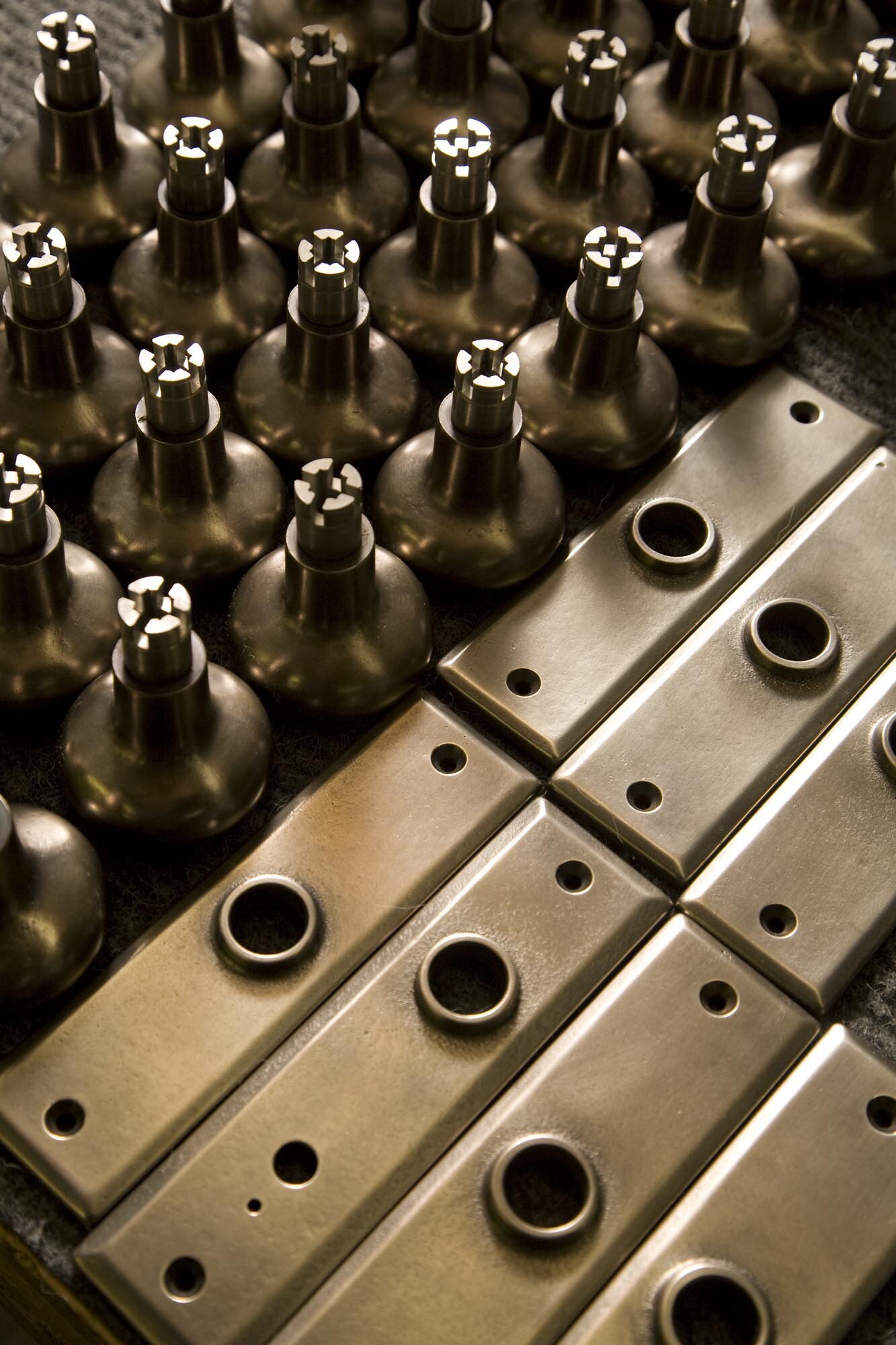

From just a sketch on a piece of paper, handcrafted patterns and 3D computer models are developed, prototypes created with a 3D printer, and a client’s vision begins to take shape. At the foundry, a carefully orchestrated casting process allows ideas to be transformed into reality. Precision machining ensures that each piece of Sun Valley Bronze hardware functions perfectly and meets our specifications.

The final stage of the process involves patination, hand waxing, buffing and final assembly in the Sun Valley Bronze finishing studio. Assembly is completed with our stainless steel components and Teflon coated springs which bring our pieces together for flawless function. Each piece, whether it be custom made or one from our collections, does not leave our shop without a final inspection.